The Importance of 3D Modeling in Dental FEA Analysis

In dental engineering, precision is not just a goal—it’s a necessity. Whether you’re working on designing a dental implant, crafting a bridge, or developing any prosthetic device, achieving exceptional accuracy during the preliminary stages is essential for ensuring the final product performs as expected. This is where the power of advanced 3D modeling truly shines.

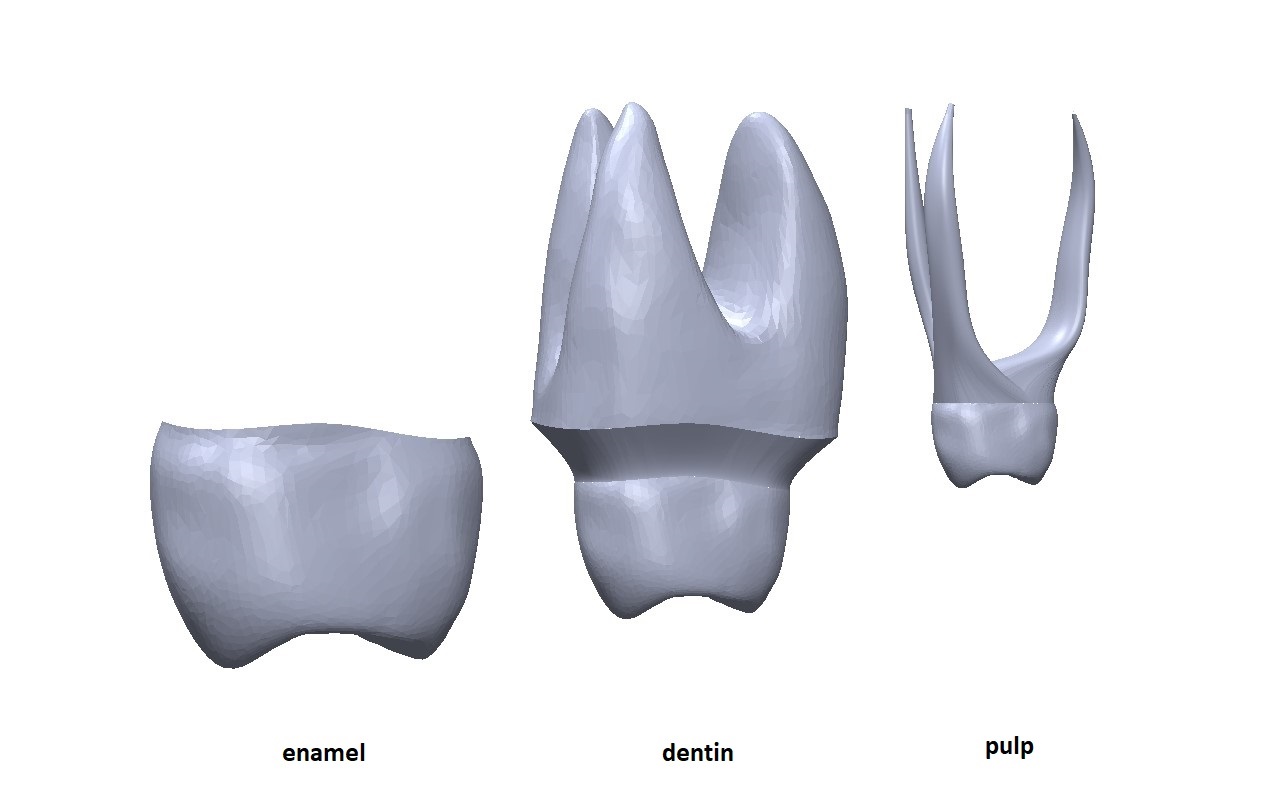

At Engineering DNA, we recognize the critical role that 3D CAD modeling plays in developing dental applications. Before conducting a Finite Element Analysis (FEA), an accurate, highly detailed 3D model of the dental structure or product must first be created. This step is vital, as the quality of the initial model directly impacts the reliability and precision of the FEA results. At Engineering DNA, we specialize in creating precise and intricate 3D CAD models, tailored specifically for dental students, researchers, and professionals focused on innovation in the dental field.

Our 3D modeling process is designed to capture every minute detail of the dental structure with unparalleled accuracy. Whether it’s the delicate curves of a dental crown or the intricate geometry of a full-arch bridge, we ensure that every feature is meticulously represented in the virtual design. This level of precision is not only critical for creating functional dental prosthetics but also plays a key role in simulation accuracy when performing FEA. Inadequate modeling can lead to misleading FEA results, which could result in the failure of the dental device under real-life conditions. Therefore, ensuring that the 3D model is flawless is paramount to the overall success of the project.

Finite Element Analysis (FEA) itself is a powerful tool used to simulate and predict how the dental prosthetic will behave under real-world conditions. During FEA, we can simulate forces such as chewing, biting, and other stresses the dental structure will endure in the mouth. By analyzing how these forces impact the prosthetic—predicting stress points, areas of strain, and material behavior under pressure—we help ensure that the design is not only functional but durable, comfortable, and reliable for long-term use.

For dental students who are working on their final projects or for professionals developing cutting-edge dental solutions, partnering with an expert team like Engineering DNA offers tremendous benefits. By combining our advanced 3D CAD modeling services with comprehensive FEA analysis, we help ensure that your designs are optimized for success, minimizing the risk of failure during manufacturing or in clinical use. This collaborative process provides dental professionals with the confidence that their products will perform as intended in the patient’s mouth.

At Engineering DNA, we are proud to offer top-notch 3D modeling services and state-of-the-art FEA analysis specifically tailored for dental applications. Whether you’re a student seeking to create an innovative final project or a professional developing new dental products, our expertise ensures that you receive accurate, actionable results. By partnering with us, you can bring your ideas to life with precision, reliability, and the assurance that your design is ready for the next stage of development.