Precision Engineering: How CNC Machining Delivers Unmatched Accuracy

In modern engineering, precision is the cornerstone of quality, especially in industries like aerospace, automotive, and medical devices where accuracy can mean the difference between success and failure. CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape by delivering an unparalleled level of precision in producing high-accuracy parts.

The Role of CAD/CAM Technology

At the heart of CNC machining’s accuracy is integrating CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies. 3D modeling aids engineers in creating intricate 3D models of the desired part using CAD software. These digital blueprints capture every detail, ensuring that the design meets the exact specifications required for functionality.

Once the design is complete, the CAD file is converted into CNC programs using CAM software. This process translates the virtual model into a set of precise instructions for the CNC machine, ensuring that every measurement and detail is followed to perfection. By eliminating manual processes, the risk of human error is greatly reduced, resulting in consistently accurate production, whether the output is a single part or thousands.

Automated Precision and Complexity

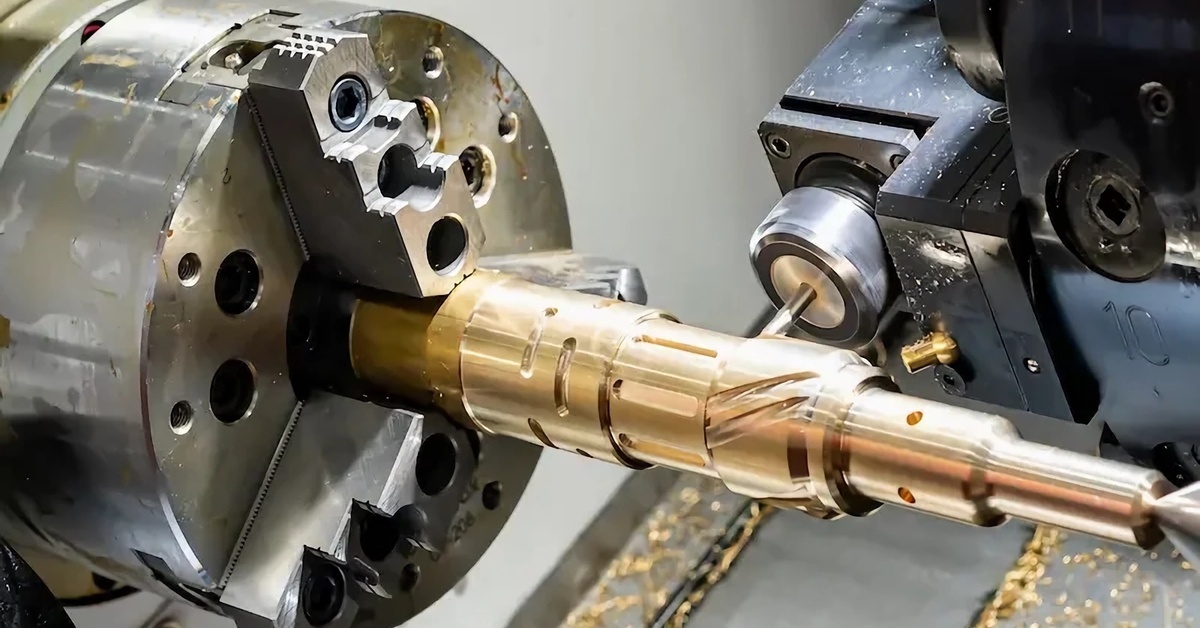

Once programmed, CNC machines carry out the operations autonomously, removing the need for constant human intervention. This automation guarantees that every part is manufactured to the same standard, ensuring repeatability. Additionally, CNC machines operate on multiple axes, allowing them to produce complex geometries that would be difficult or impossible to achieve through traditional manual methods.

Real-Time Monitoring for Accuracy

Modern CNC machines are equipped with advanced real-time monitoring systems. These systems continuously track the machine’s operations, and if any deviation from the programmed path is detected, immediate adjustments are made. This ensures the highest level of precision and minimizes material waste, making the process both efficient and cost-effective.

At Engineering DNA, we leverage the power of cutting-edge CNC machining technology, combined with our engineering expertise, to deliver precision-engineered parts for industries that demand nothing less than perfection. Whether you need prototypes or full-scale production, CNC machining ensures unparalleled accuracy and quality.